Living Hinge Plastic Canada

Regardless of the application be it a liquid powder or solid bonar can help your company solve the most difficult material handling.

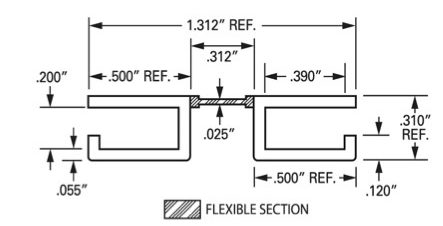

Living hinge plastic canada. A living hinge is a thin flexible hinge made from the same material as the two rigid pieces it connects. All of these hinges are pinless they have a flexible joint instead of a pin. Petro s coextruded living hinge combines impact modified acrylic wings with a polyester thermoplastic hinge membrane for full flexibility and long life. The hinge section is designed to allow rotational movement 180 degrees or greater between the sections and in a configuration where it will not fail during the life of the part.

A familiar example would be a ketchup cap. These are commonly found on plastic packaging dispensing caps and thermoformed clamshell packaging like the one you see below. The purpose of the hinge on a ketchup cap is to keep the cap connected to the main body but also allowing it to move out of the way for dispensing. A living hinge is a thin piece of plastic surrounded by thicker plastic that allows a part to fold or bend from 1 to 180 degrees.

They are very durable and with good design can last for millions of cycles. In this post we will go over a very quick technique for modeling a simple flat living hinge as a single. A living hinge is typically a thin section of plastic that allows a part to fold as if it was hinged. A living hinge is a connected portion of a whole part that is thin and flexible enough to allow movement between two otherwise rigid sections of the same part.

There are a few ways to implement a. The minimal friction and very little wear in such a hinge makes it useful in the design of microelectromechanical systems and the low cost and ease of manufacturing makes them quite common in disposable packaging. See more ideas about living hinge laser cutter ideas laser cut wood. If it is too thick it will create too much stress and the part will fracture.

It is typically thinned or cut to allow the rigid pieces to bend along the line of the hinge. It is possible to make viable hinges with parallel orientation in the case of extrusion for instance if your design requires it but you won t be maximizing the strength of your material. If plastic is too thin it may not have the necessary strength and the part may tear. But as the part bends it creates strain called tensile stress.

Jun 24 2014 explore dcoole25 s board living hinges on pinterest. They also have a standard clearance when they are closed the distance between the leaves is about half. This type of. A living hinge is a thin section of plastic that connects two plastic bodies together.

Plastic hinges are a lightweight alternative to metal hinges and provide smooth silent operation. Longer than other hinges piano hinges run the entire length of doors and lids for strength and durability. Bonar plastics has been a recognized leader in the design and manufacturing of material handling container solutions for over 50 years which has resulted in the industry s most diverse product offering in both standard and custom design configurations. Orientation of the plastic molecules highly affects the strength of the joint and consequentially the hinge strength.