Laser Plastic Welding Ppt

Learn new and interesting things.

Laser plastic welding ppt. There are many advantages to the new potomac laser welding process explains natalia which will open new manufacturing options in industries from microfluidics and medical devices to consumer products and aerospace. They are welded by melting the surface to be joined allowing them to solidify as they solidify the methods for joining plastic components can be divided into three major categories. Plastic welding powerpoint ppt presentations. Welding jigs and fixtures purpose 1 to minimize distortion caused by heat.

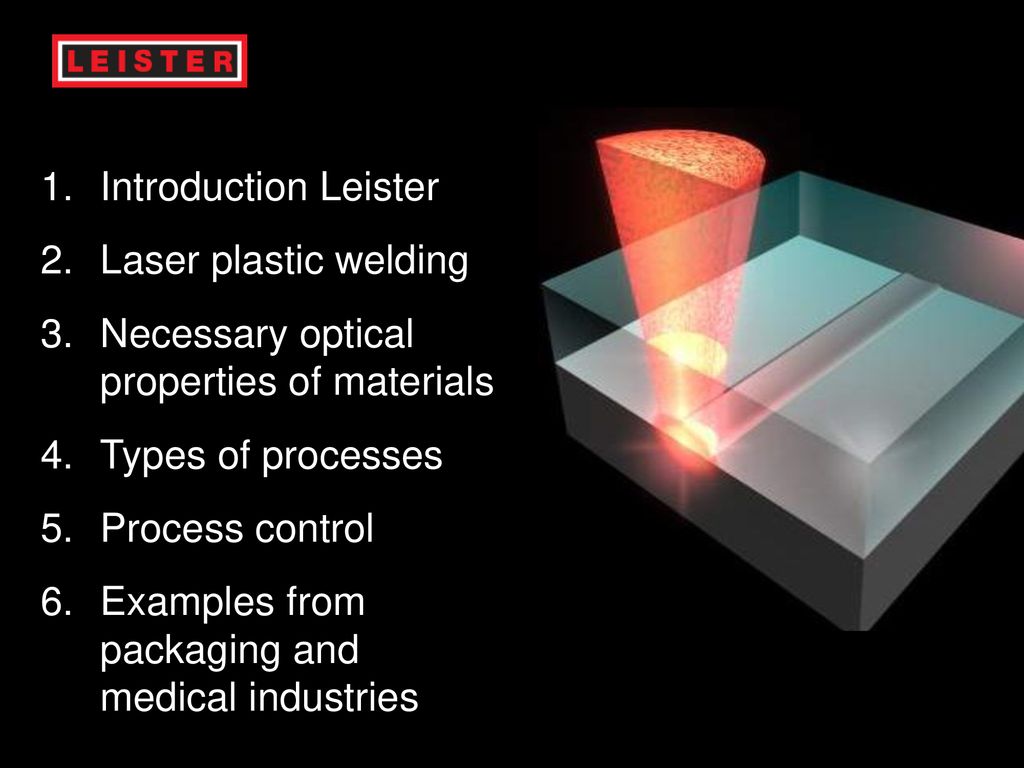

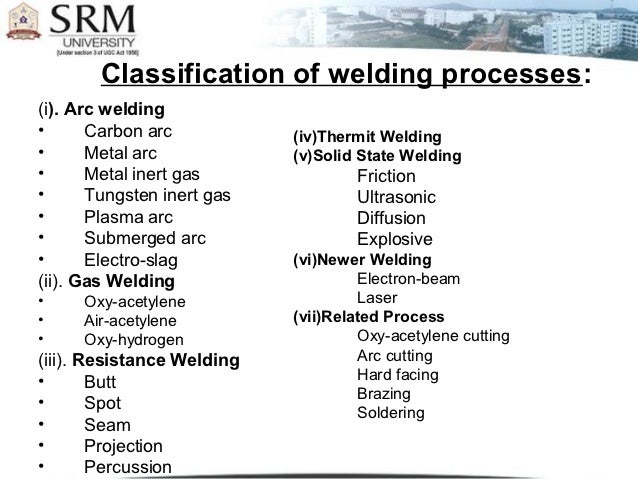

Nelson consultant engineer sapphire ball 500 micron top plastic layer here is a close up view of the focal region where the fusion bond is made weld bond line at interface between plastic layers focal spot parameters focal spot parameters 5 mm 2 3 mm 1 5 mm 7 5 mm 1 0 mm 1 0 mm 6 35 mm. The process is very much different than traditional metal welding. Most commonly welded plastics are pvc polyethylene acrylics etc. Contents 0 introduction 0 classification of plastic welding 0 hot plate welding 0 hot gas welding 0 ultrasonic welding 0 friction welding 0 laser welding 0 conclusion 0 references.

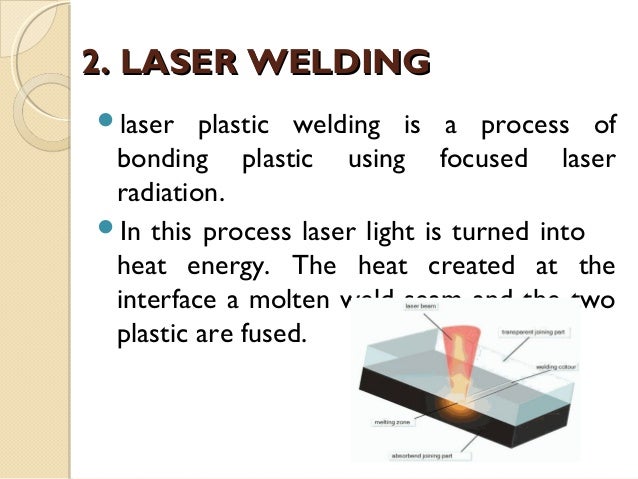

Laser plastic welding also often referred to as through transmission welding is a process of bonding plastic using focused laser radiation. Get ideas for your own presentations. The process relies on passing. Introduction thermoplastics can easily be welded as can regain their shape after heating.

Ashish 11681a0328 christu jyoti institute of technology science colombonagar yeshwanthapur jangoan dist. Laser welding optical system suitable for fusion bonding suitable thermoplastic polymer materials craig e. Seminar reports presentations. For laser welding if the joint surface has a gap which influences the welding strength.

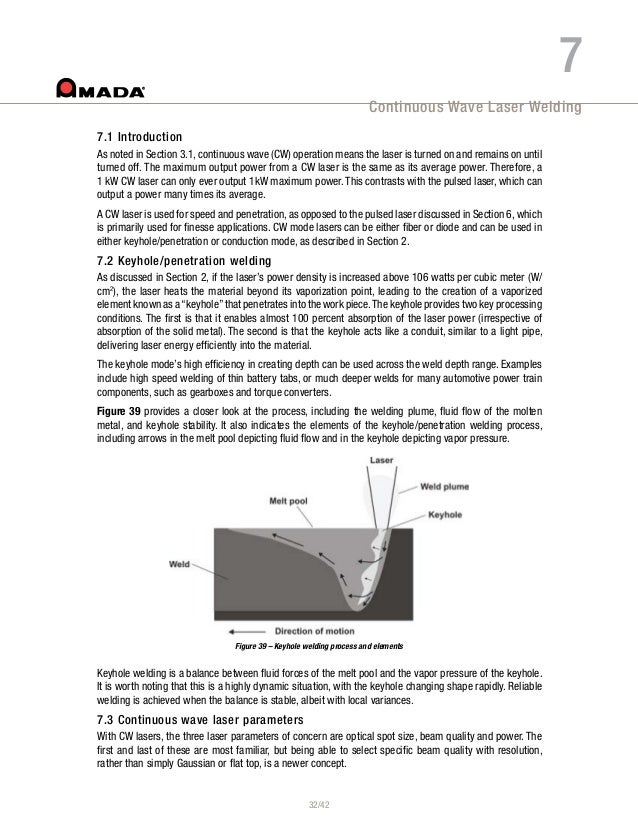

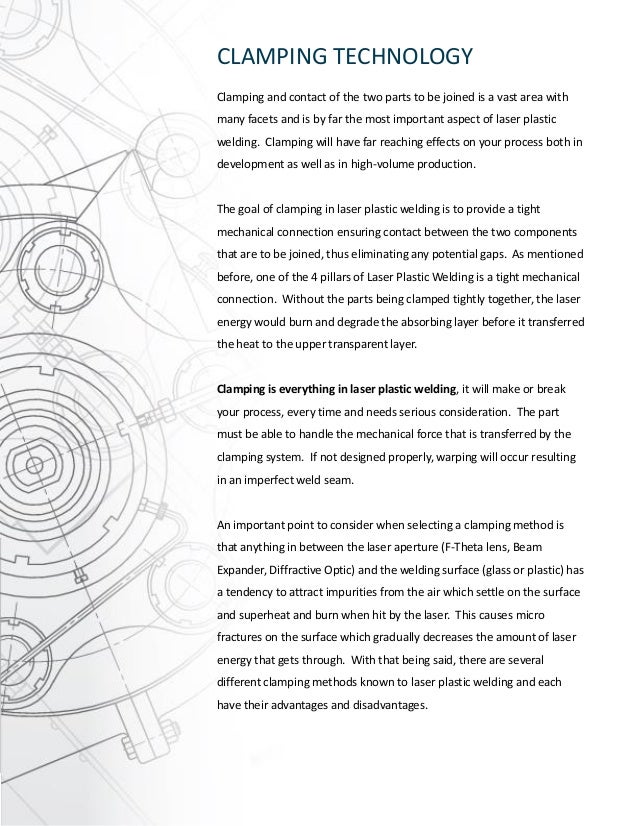

Share yours for free. Also explore the seminar topics paper on plastic welding with abstract or synopsis documentation on advantages and disadvantages base paper presentation slides for ieee final year mechanical engineering me or production automobile students for the year 2019 2020. The main causes of gaps include warpage and shrinkage of the molded product. The laser light is turned into heat energy as.

Welding of plastics presented by. Are you interested in any one of the topics. Download the seminar report for laser beam welding. Leading the potomac ppt effort in laser welding senior technical researcher natalia christensen has recently developed a new process to laser weld clear plastics that are between 50 and 200 microns thick.

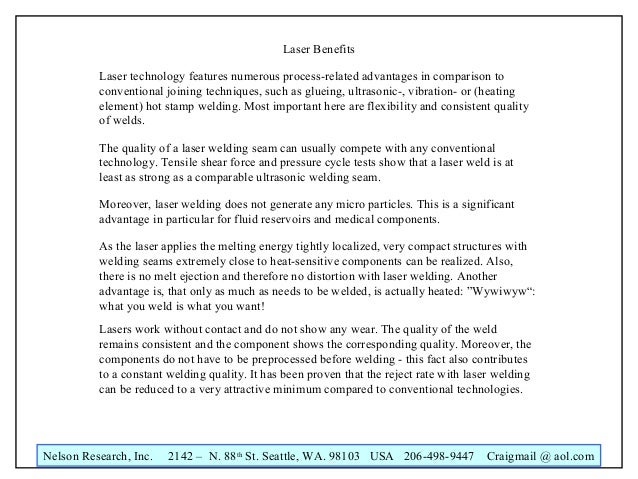

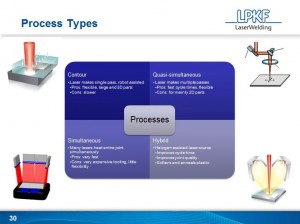

The concept involves passing a focused laser beam through an upper laser transmissive part to the interface of the two parts to be joined. Higher joining quality minimal resulting flash or particulates higher quality controls less stress to the component and can weld complex and intricate shapes. The results are shown in figs. Although there are many methods for joining thermoplastics laser plastic welding has a few clear advantages.

A spacer was inserted into the overlap between the transmitting material and the absorber to create a dummy gap as shown in fig. Download laser beam welding seminar reports ppt pdf laser beam welding seminar topics abstracts full documentation source code. Laser plastic welding is a method of bonding two or more thermoplastic components together. 10 28 and laser welding was executed.